All Services

we provide a comprehensive range of industrial engineering, process automation, and technical solutions designed to optimize manufacturing operations

Process, Filling, Packaging and Inspection Systems

Comprehensive solutions for Process, Filling, Packaging, and Inspection Systems across RGB, PET, CAN & KEG.

Syrup Room Installation, both Mechanical & Electrical

We handle complete Syrup Room installations, both mechanical and electrical.

CO2 Plants Installation

We install CO₂ plants with precision, ensuring safe, efficient, and reliable systems for your production needs.

Milk Processing Plants Installation

We install milk processing plants, making operations smooth, efficient, and fully compliant with industry standards.

Caustic Filtration Systems

We install and maintain Caustic Filtration (Aquarex) Systems to keep your processes efficient and cost-effective

Process Plant and Brewhouses Installations

We install process plants and brewhouses, handling pipework, mechanical, and electrical systems.

Water Treatment and Purification Systems

We help maintain sustainable water access through a combination of physical, chemical, and biological processes to eliminate harmful substance from water.

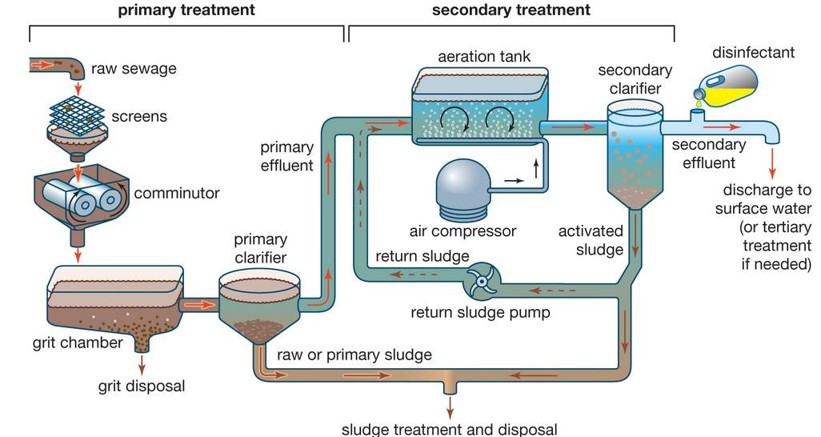

Waste water management systems

We ensure efficient treatment, and disposal of waste, tailored to meet the specific needs of commercial, and industrial clients.

Other Services

- Decommissioned and commissioning of bottling lines

- Plant shut downs

- Bottling plants maintenance, overhauls’ repairs

- Plant spares sourcing and supply

- Bottling plants audits and optimizations

- Plant electricals and automations

Training Services

Basic/advanced Electrical Training

Basic/advanced programmable training

Machine Specialist Training

Machine Operator Training

Machine Maintenance Training

Process Training

Consultancy Services

Green field plant conceptualisation, design and setup to customer specifications

▶ Design of process, filling and packaging line layout diagrams to customer specifications

▶ End to end turn key project planning and support

▶ Project management

▶ Planning of demand, inventory, capacity and production

▶ Line analysis, process monitoring, operational efficiency and improvements

▶ Energy and media analysis and management